WTI: How do you incorporate the Art of Fusion in a Hublot?

MB: If we break down our slogan - and consider this from an R&D perspective - the word fusion comes from the Latin word fusio and the verb fundere, meaning “to melt”. So, 'fusion' means melting at least two different substances in order to form one. What makes this 'fusion' art is the real know-how and the research which helps to bring it all together.

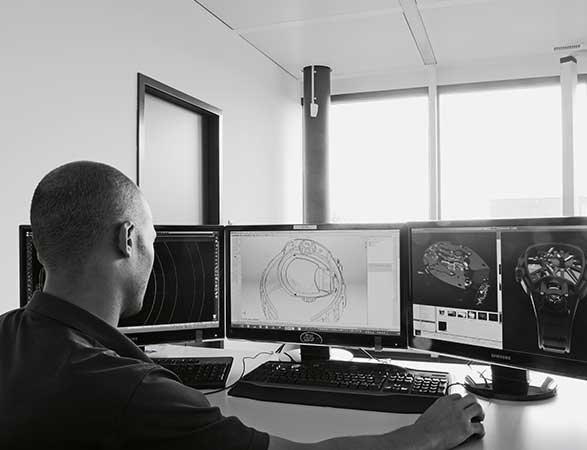

The Research & Development team works hard on all innovations keeping both the things in mind, thereby giving birth to the Art of Fusion – the true definition of a Hublot.

WTI: What are the steps involved in developing a watch at Hublot?

MB: For me, the steps involved in designing a watch can easily be compared to those in the automobile industry. Though the concepts may vary, a watch also works on a motor (the movement) and a body (the watch case) just like an automobile. For example, a Formula One car is thought and designed around the engine, keeping one main performance based objective in mind – to win a race or break records. This is what we follow at Hublot. Whilst designing the Ferrari 50 days of Power Reserve watch, we first designed its engine – the “world record” 50 days power reserve movement. We then equipped it with a tourbillon, similar to a V12 engine equipped with a turbo, and then the body was designed around this exceptional engine. The result, as you know, was a great success, both from the technical and aesthetic point of view.

Though some of our timepieces may seem to be designed only from an aesthetic point of view, it is not true. At Hublot, we maintain a fine balance (fusion) between Art and Technology.

WTI: How is a Hublot tested?

MB: There is a wide range of standardised tests in the watchmaking industry which are referenced as per the NIHS (Normes De L'Industrie Horlogere, Suisse) standards. Hublot meets the conventional tests and standards in all these cases. However, as Hublot makes further innovations, both in terms of material and movement, it goes without saying that we are obliged to define our own criteria of quality and tests. We are, in fact, constantly developing appropriate tests to go along with our innovations to ensure high quality and comfort.

WTI: How have the various testing techniques evolved over the years?

MB: I think we are totally in tune with other industries. All the designs are realised on a software that allows to simulate a great amount of external attacks. Laboratory tests are also automated. However, what makes a Hublot stand apart is that the watch is always tested on the wrist of the customer it is designed for. Therefore, you will never find a Hublot model whose prototype has not been tested on a collaborator for that specific field (football, ice hockey, skiing, golf etc). The performance of the prototype of the watch on the wrist of the collaborator, certifies it for the market.

WTI: Any hints on the next big innovation coming up from Hublot's R&D department?

MB: For reasons of confidentiality, I cannot reveal the subject of our research, but I can give you certain insights which are unique to the world of watchmaking. It is true that in the last few years, we have reached the physical and technical limits of materials which are commonly used to design a watch. We cannot make lighter or thinner components, since we've already reduced the thickness so much that if we go any further, the components might become transparent. Such dimensions will not produced the expected effects from a timepiece, such as, spring, friction, solidity etc. However, without revealing the subject of our current development, I may say that the R&D department at Hublot has chosen to develop new materials which will allow us to push the mechanical limits even further. The first model may be expected in 2018.