As watches developed over the years, so did the quality checks and certifications that proved their accuracy and reliability. Certification done today, both independent and in-house, put timepieces to a series of rigorous checks to provide the seal of quality. Below are ten important watch certifications that test the quality of watches and their movements.

COSC (Contrôle Officiel Suisse des Chronomètres)

The COSC, short for Contrôle Officiel Suisse des Chronomètres or Official Swiss Chronometer Testing Institute, is one of the most well-known and widely used certifications for chronometer movements. Founded in 1973, COSC is a non-profit organisation with offices in Geneva, Biel, and Le Locle. The Federation of the Swiss Watch along with five cantons, forms this organisation.

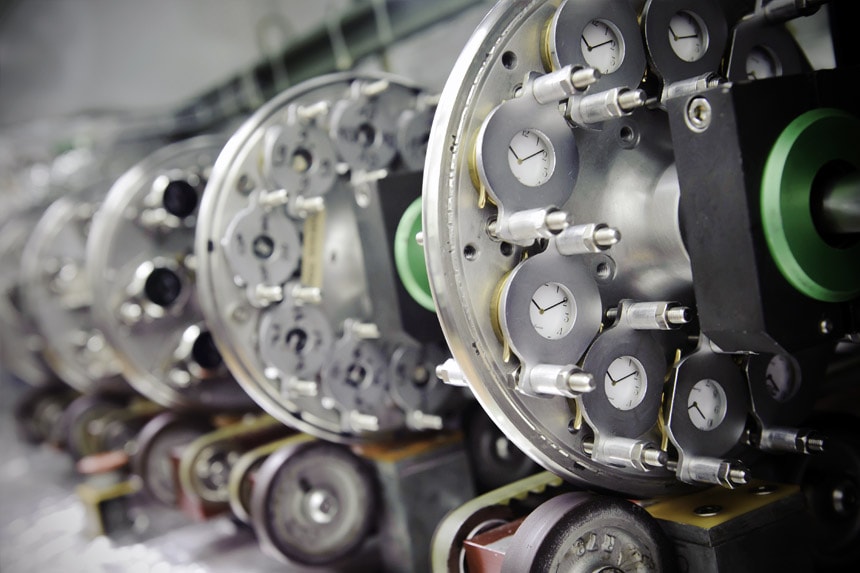

COSC certifies uncased watch movements through parameters of temperatures at 8°C, 23°C, and 38°C in five different positions, which takes about 15 days for one watch. The average deviation should lie between -4 to +6 seconds per day, followed by seven eliminatory criteria. If the chonometer passes it all, it gets COSC certified. Each COSC-certified watch can be identified by the certification number and the serial number which is engraved on the movement.

Nearly all watch brands get all of their movements certified by COSC. However, for Rolex, the criteria for getting the certification is only ±2 seconds of deviation rate per day, making Rolex’s chronographs one of the most precise movements. All the criteria are laid out in DIN 8319 and ISO 3159 standards, which can be reviewed by anyone.

Poinçon de Genève or Geneva Seal

Also called Geneva Hallmark, every mechanical watch manufactured in the Canton of Geneva is certified with the Geneva Seal, guaranteeing that the timepiece has been created in Geneva. One of the oldest and the most difficult movement standards to achieve by any brand, the Geneva Seal checks for the decoration and finishing of the mechanical movements. A Geneva-based watchmaking and microtechnology lab, called Timelab, has been issuing the seal since 2009.

To get the Geneva Seal, the watchmaker has to submit the application if its watch movement has been entirely made in Geneva which includes assembling, calibration, and encasing. The manufacturer is also required to be enlisted in the commercial register of the Canton of Geneva. As of now, Cartier, Vacheron Constantin, and Roger Dubuis are some of the brands among those that are certified by the Geneva Seal for their movements.

The Patek Philippe seal

Image: Brand

Image: Brand

Since 2009, Patek Philippe has been embossing all its mechanical movements with the Patek Philippe seal. After 123 years, the Swiss brand replaced the Geneva Seal with a higher-standard seal of its own. Under the terms of its seal, Patek Philippe offers the watch industry’s first promise of lifetime service on the watch. For calibers with diameters of 20 mm or more, the accuracy must be within -3 and +2 seconds per day. For calibers with diameters of less than 20 mm, the accuracy must be within -5 and +4 seconds per day. The requirements for tourbillon watches are even tighter. Patek performs its rate tests in several phases of the manufacturing process. The final tests are conducted on fully assembled watches. The seal can be identified by the ‘PP’ emblem stamped on the movement. Patek Philippe seal takes into consideration a more comprehensive assessment of the watch in whole as compared to the Geneva seal.

METAS (Swiss Federal Institute of Metrology)

The METAS Master Chronometer certification is an extensive certification for chronograph watches, which includes all of a watch's primary functional features such as precision, resistance to magnetic fields, waterproofness, and power reserve. It was brought into effect by the Swatch Group in 2015. To qualify for METAS, a watch must first be certified by COSC.

Image: Brand

Image: BrandA watch is subjected to a 4-day testing process in everyday conditions where at a certain point it is exposed to the magnetisation of 15000 gauss and then it is demagnetised. Here the watch must be able to operate within a 5-second range of variation each day (0/+5). Following this, the watch gets evaluated between 100% and 33% power. The watch spends 30 seconds in each of the following positions throughout this test: dial-up, dial-down, crown-up, crown-down, crown-right, and crown-left. Again, it shouldn't deviate from a precision of 0/+5.

Quality inspection by the Foundation Qualité Fleurier or Fleurier Quality Foundation seal (FQF)

Finished mechanical watches developed in Switzerland are given "QUALITE FLEURIER" quality label issued by the Fleurier Quality Foundation (FQF).  Image: Brand

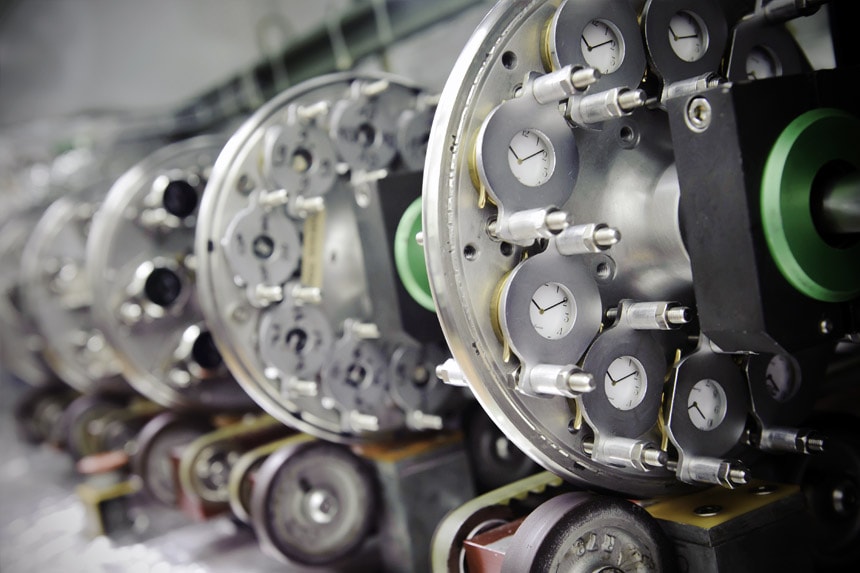

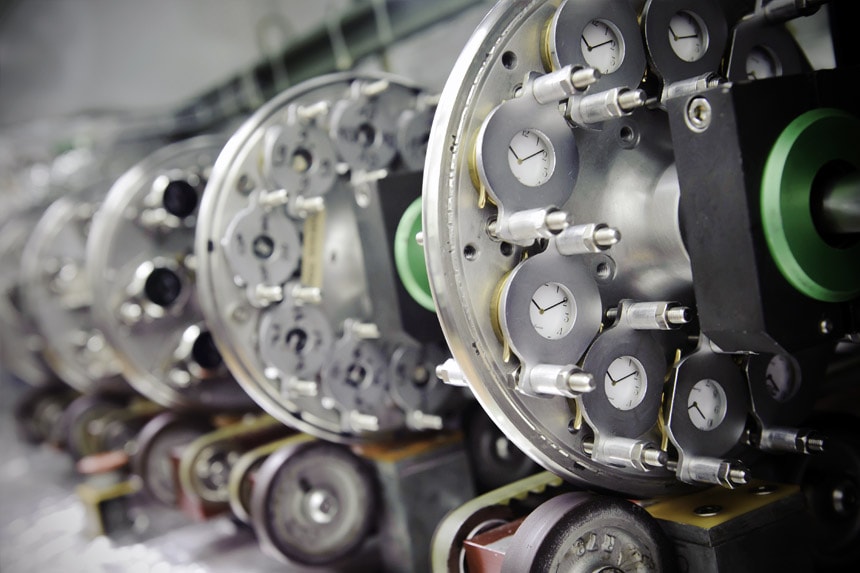

Image: BrandThere are five stages of control that a watch must pass to get the FQF seal. First, the watch must be completely manufactured in Switzerland starting from the design, assembling, and quality checks. Raw materials used are an exception here. Second, the watch must meet the quality standards laid out by the FQF, which can be found in the “Definition of technical and aesthetic criteria” section on www.fqf.ch. The third requirement is that the movement must have passed the COSC test. Next is the Chronofiable® ageing test which is done and certified by the Dubois SA laboratory based in La Chaux-de-Fonds. Lastly, the watch needs to pass the 24-hour test programme on the Fleuritest simulator, whose criteria are laid out in the “Final control on the Fleuritest simulator” section on its website.

The founding members of the Fleurier Quality Foundation were Chopard, Parmigiani, Bovet, and Vaucher.

The 500-Hours certificate by Montblanc

Each watch from Montblanc Le Locle is subjected to a rigorous 500-hour test which ensures the reliability of the brand’s timepieces. The three-week-long test simulates the watch on the wrist in real life and guarantees that the watch would not require any repairs before its first routine servicing.

Image: Brand

Image: BrandThere are 5 tests in the process, starting from the Winding Performance and Assembly Control which goes on for 4 hours and checks for winding performance and if the final assembly of the watch is done correctly. Second is the Continuous Accuracy Control for the next 80 hours which monitors the rate of movement in all positions. The next is the Functions Control for the longest duration of 336 hours where the watch is tested for its overall functioning. Test four is the General Performance Test which checks the momentary rate and functions of the watch in all positions for the next 80 hours. The final test is the Water Resistance Test for the last 2 hours.

A Montblanc watch is only released for sale after it passes the 500-hours test.

Ulysse Nardin Performance Certificate

Ulysse Nardin introduced its Chronometer & Performance Certificate in 2012 to test two of its in-house movements, the Caliber 118 which is used in the Marine Chronometer Manufacture, and the Caliber 150 used in Marine Chronograph Manufacture. The test goes on for seven days and includes aesthetic inspection, water-resistance test, and vacuum and pressure tests where the watch is put under -0.6 bar and +2.5 bar air pressures. The main part here is the five-day test of the accuracy of the watch where it is put into checks in six positions, each for 20 hours, and three temperatures (8, 23, and 38ºC). The range deviation allowed here is -2 to +6 seconds per day, and the effect of temperature is ±0.5 seconds/day per degree.

Superlative Chronometer Certification by Rolex

Since 2015, all Rolex watches go through the Superlative Chronometer Certification that tests the brand’s timepieces for chronometric precision, waterproofness, self-winding, and power reserve. The tests are carried out in-house in Rolex’s laboratories after the watch has been completely assembled.

Image: Brand

Image: BrandFor precision check, a Rolex watch is sent to COSC for 15 days and nights each where it is tested in five positions and three temperatures. Following this, all movements in Rolex watches are certified chronometers. The rate deviation allowed here is −2/+2 seconds per day. The waterproof test is carried out in a hyperbaric tank where for water resistance of 100 metres is checked at its rated depth plus 10% and for diver watches (300m, 1,220m, and 3,900m) the margin is 25%. At the beginning of the test, the watch is fully wound to check for its stated power reserve and verified for self-winding such that no part should obstruct and must work optimally after it is cased.

Image: Brand

Image: BrandA successful Superlative Chronometer Certification can be identified for a watch by looking at its dial which is inscribed by ‘Superlative Chronometer Officially Certified’ for the Oyster Perpetual collection except for the gem set timepieces. The certification is also testified by the green seal that comes with every Rolex watch and also symbolises its five-year international warranty.

Besançon Observatory

Located in Besançon, France, the Besançon Astronomical Observatory is an observatory from the 19th century which was able to measure and set time accurately. The Observatory was first established in 1885, then it closed in 1970 and reopened in 2002. Almost 100 watches are certified by the observatory per year of brands such as Akrivia and Kari Voutilainen, among others. Here the chronometer watches in their final assembled form are tested according to ISO 3159 standard for 16 days in 5 different positions and 3 temperatures. The average rate deviation accepted here is -4 to +6 seconds. Once passing the test, the watch is given its number along with its certificate and stamped with its Viper symbol.

Chronofiable

Image: Fleurier Quality Foundation

Image: Fleurier Quality FoundationChronofiable tests first started in the 1970s, just as observatory contests were coming to an end. During this time, the Federation of the Swiss Watch Industry established the Reliability Test Centre and trademarked the term "Chronofiable." Chronofiable is now a subsidiary of the Laboratiore Dubois SA, an independent horological testing facility. The Chronofiable tests, on the other hand, have stayed virtually unmodified since their start. These tests go on for 21 days and replicate six months of wear. The watch is checked in terms of shock and temperature fluctuations.